PaveCoat AntiSlip Mix In

For freshly paved concrete surfaces

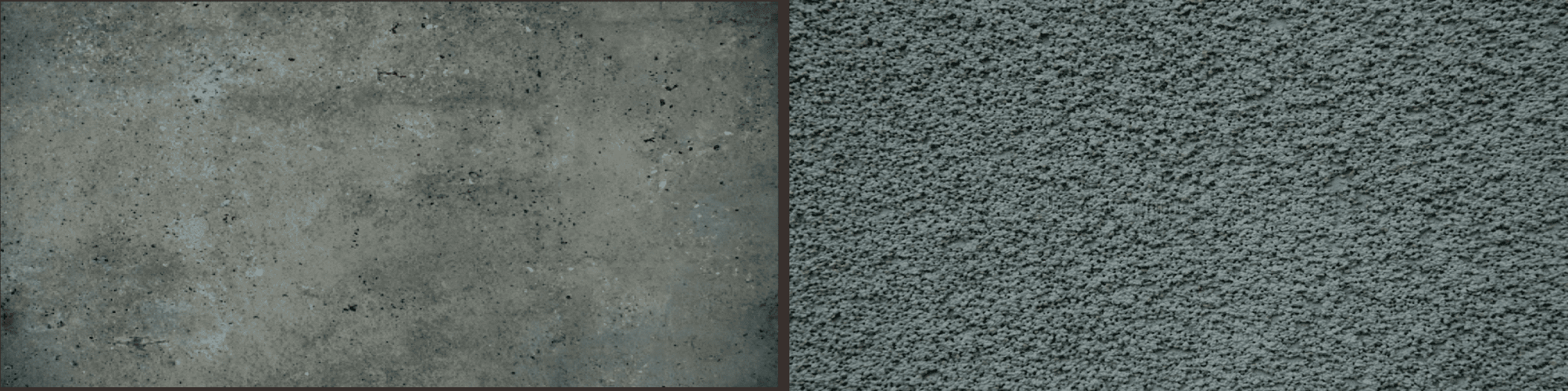

PaveCoat AntiSlip Mix In has been developed to increases the friction coefficient of all NuTech single pack floor coating systems, reducing the slip potential under both wet and dry conditions.

As a mix in additive, it has been designed for use in the NuTech single pack sealer and coating systems such as; PaveCoat, PaveCoat Petrol Resistant, PaveCoat H2O and EPiC Industrial Enamel.

Features

- Substantially improves safety of sealed surfaces in wet and dry conditions

- Simple mixing to achieve a uniform distribution

- Flexible and scuff resistant

- Less abrasive surface to reduce personal injury due to falls

AntiSlip Mix In when applied in the correct methods, will achieve a Pendulum Classification of P2 or P3 and meets AS4586 & AS4663.

Please refer to the NuTech Paint ANTISLIP SKID TEST Fact Sheet for further details.

AntiSlip Mix In IS NOT suitable for inclined or steep surfaces.

NOT RECOMMENDED for use in 2 pack concrete finishing systems OR in AquaStop or Silicon Sealer.

NuTech recommends the use of PolyCryl and the addition of AntiSlip Cast On to achieve up to an R12 or P5 slip rating.

Refer to the relevant TDS for further information.

Application Guide

For detailed substrate preparation and application steps, please download the full application guide.

Preparation

Test Patch:

NuTech Paint recommends that applicators test any AntiSlip system first as varying surface profiles, slopes and access conditions vary significantly with individual conditions. These variants impact heavily on pedestrian and vehicle safety.

Application Procedure:

1 st Coat:

- Mix and apply first coat of the selected NuTech sealer in accordance with the relevant TDS and application method, allow to dry.

NOTE: AntiSlip Mix In is only required in the final topcoat of the NuTech Paint system.

2 nd Coat:

- Mix the selected NuTech Paint system in accordance with the relevant TDS

- Add AntiSlip Mix In in the following ratio; Mix ratio: (optimum performance) P2 Rating - Min. 400 grams (1 tub) per 20L of Paint product P3 Rating - Max. 800 grams (2 tubs) per 20L of Paint product

- Stir into the NuTech Paint system product to be used for top coat

- Stir well until no visible lumps

- Allow to stand for 10 minutes, re-stir prior to use

- Keep blended product agitated

- Apply mixed NuTech Paint system in accordance with the relevant TDS and application method A small amount of dry AntiSlip Mix In can also be broadcast onto the surface and then painted over for extra non-slip properties.

Note: Refer to the table regarding AS4586 & AS4663 mix ratio requirements Increasing the quantity of AntiSlip in the topcoat will increase the surface friction however, AntiSlip Mix In may become visible or leave a patchy appearance if over added.

ReCoat:

AntiSlip Mix In is to be added and applied in the final coat only. Refer to specific NuTech system TDS for specific re-coat times.

Typical Applications:

Ideal around wet areas, pools, factory loading docks, access ramps (with less than 15 degrees incline), stairs, entrance foyers, public pedestrian and vehicle areas.

Warnings

AntiSlip Mix In IS NOT suitable for inclined or steep surfaces.

NOT RECOMMENDED for use in 2 pack concrete finishing systems OR in AquaStop or Silicon Sealer.

Nutech recommends the use of PolyCryl and the addition of AntiSlip Cast On to achieve up to an R12

or P5 slip rating. Refer to the relevant TDS for further information.

Safety Precautions

Based on available information, this material is not classified as hazardous according to criteria of Safe Work Australia.

PaveCoat AntiSlip Mix In

Quick Reference

Appearance:

Dry white powder

Coats Required:

2

VOC Levels:

85%

Ambient Application Temperature:

10°C - 30°C

Coverage Rate:

5 m2/L

Properties

Related Products:

Important Notice

The information given in this data sheet is based on many years experience and is correct to the best of our knowledge. However as the use of our product is beyond our control we can only be responsible for the quality of our product at the time of dispatch. For additional information about specifications or application please contact our company. As this information is of a general nature we cannot assume responsibility for individual use.